- HOW TO USE CUTVIEWER MILL HOW TO

- HOW TO USE CUTVIEWER MILL UPDATE

- HOW TO USE CUTVIEWER MILL VERIFICATION

HOW TO USE CUTVIEWER MILL HOW TO

How to Download and Install Cut Viewer Mill 3.2 G Codes Used in CNC Milling M Codes Used in CNC Milling. Bringing stunning visuals, technological innovations driven by a highly-dedicated. Use of Function Keys F1-12 and some shortcuts. Another common term used is GCode or G-Code. Free cutviewer mill simulator download software at UpdateStar We have always loved making truck-driving games and Euro Truck Simulator 2 was our first big success in the genre. The detailed process on how we use it is shown in a separate Article. The web site of CutViewer gives a good introduction on the principles. remember folks, dont use gloves on a mill. View Entire Discussion (9 Comments) More posts from the CNC community.

HOW TO USE CUTVIEWER MILL VERIFICATION

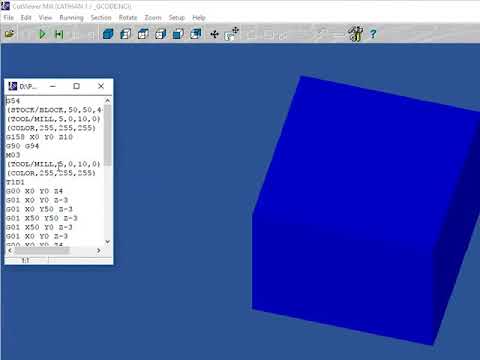

Than the cut for every tool in CV is displayed into a different color. We use Cutviewer for the CAM Verification Process. If you need gcode testing then cutviewer is what are you looking for-2. The color, in this case "COLOR,225,90,11" you can change for every tool. If you use a ballmill with 3mm you put 1.5 into Vee Angle. If you use a ballmill cutter you put the half diameter of the tool in Vee Angle. CutViewer - United Kingdom 0.010 mm +- 0.005 mm 0. In your postprocessor you change the "post file" section to (in this example the default pp): You have to prepare your postprocessor a little bit and the tools in the tool library for good working together, then all your informations about stock and tools are comming directly from cambam to cv. It also gives me rough approximations of the machining time, which is of some particular worth to me. CV gives that confirmation, and allows me to measure, view, and rotate views. I make machines, and must verify that the cuts that I wish to make are the cuts that will be made. I could not live without CV as an adjunct to CamBam - or at least, not without some good milling simulator. Machining Simulation is an application especially designed to help.

HOW TO USE CUTVIEWER MILL UPDATE

Update milling cutter to round nose milling cutter. Each time you run a job, it will ask you for the tools - but if they are in the library, you merely select them and go on. What's new in Machining Simulation 2.1.5.5 Mill: Fix of radius compensation. Magic Recovery Professional 3. Once you build those tools in CutViewer's library, they will be available to every job you simulate with it. CutViewer Mill 3.2 & CutViewer Turn 3.2 CutViewer is an easy-to-use program that simulates 2, 2-1/2 and 3 axis CNC Machines removing material from. CutViewer wishes to know the diameter, the length, the tip geometry, and the taper. CamBam works with the tool diameters you've specified in each MOp, but that information - and the tip geometry - do not fully define a tool. However, the tools must be 'built' in the CutViewer tool library. This is an easy-to-use application that graphically displays the material removal process for milling / drilling operations in 2, 2.

Based on the stock statements and tool definitions, CutViewer will show you exactly what material will be removed from a raw stock. If you fully define your stock in the "Machining" tab in the project view, CV won't ask for the stock. CutViewer Mill V3.1 is an easy to use program that graphically displays the material removal process for milling/drilling operations in 2, 2.5, or 3 axes.

0 kommentar(er)

0 kommentar(er)